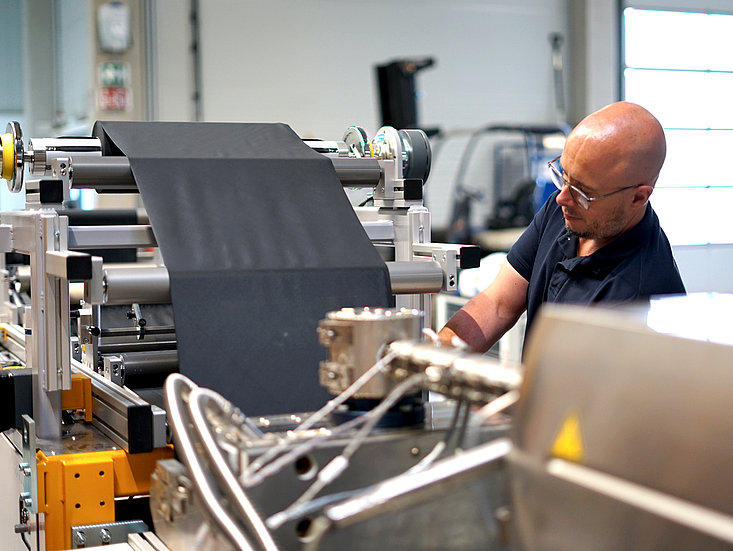

Functionalisation of Textiles by Coating.

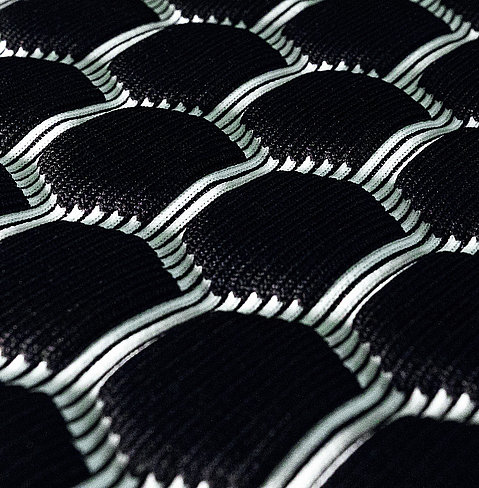

Coating textiles with polymers enables a variety of different functionalities. In addition to the powerful bonding of textiles, other functions such as UV protection, barrier, breathability, and material reinforcement can be integrated. The polymers used are thermoplastic co-polyesters, polyurethanes and polyolefins such as polyethylene and polypropylene.