Turning Tradition into Innovation - Weaving With Shuttle.

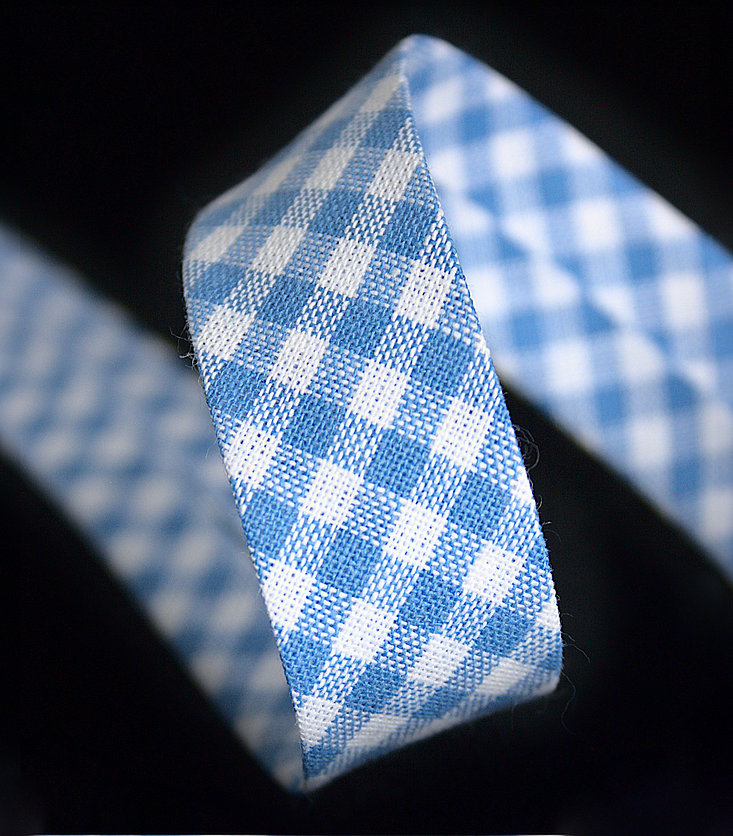

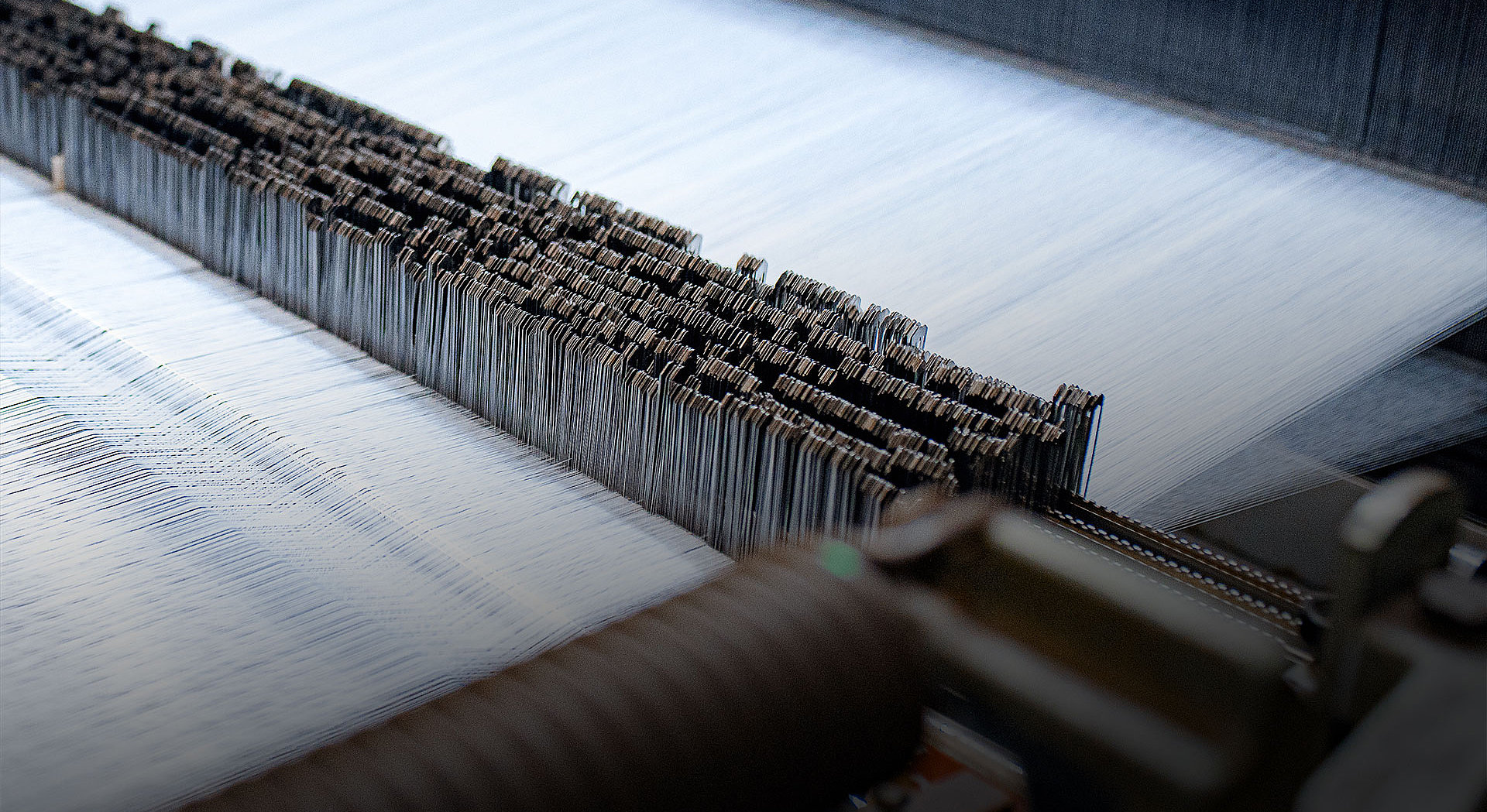

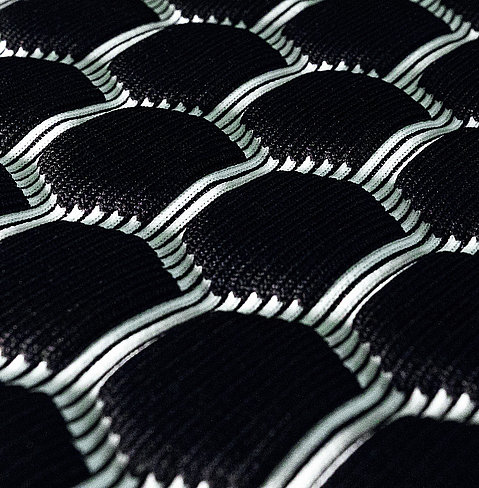

In the 1940s, our founder Gerhard Topp industrialised the bias binding production. He developed the process that is still used today to convert woven tubes into elastic bias fabrics. Since then, tube weaving has been an important part of Topp Textil and it is impossible to imagine bias binding production without it. So far the only way to produce them is by traditional shuttle looms.

After the weaving mill was closed for a period of time, it has once again been an integral part of production since 2011. Various flat and tubular fabrics are now produced there, primarily for the company's own further processing.